How Blow Moulding Works?

The procedure of blow moulding is widely used in the industrial world to make high-quality plastic products. Similar to other moulding techniques, it involves forcing a heated liquid substance into a mould chamber and then applying pressure to help create its shape. Blow moulding utilises a specific moulding technique that not many people are aware of. If you are curious or interested in how the process of blow-moulding is done, then we are here to help you learn more about this topic!

In this article, we will be going over how blow moulding works and the technology used behind it so you can see the benefits it provides to companies.

What is the history of blow moulding?

Blow moulding originates in glassblowing, in which an artisan would heat the glass to its melting point and then inflate it by blowing it through a tube. This procedure dates back to the nineteenth century. A patent from the era demonstrates the usage of celluloid polymer in the method. These early methods did not lend themselves to mass production. The first material other than glass to be utilised for blow moulding was natural rubber.

In the 1850s, Samuel Armstrong patented the method. The 1930s saw the mass production of blow-moulded bottles made practical by developing commercial machines. The available materials were too brittle and took too long to create for the technique to be utilised efficiently for mass production. With the development of low and high-density polyethene, blow moulding exploded in industrial popularity. This revolutionised numerous industries, including the automotive and soft drink bottling industry.

What exactly happens during blow moulding?

The blow moulding process involves blowing hot plastic into a mould cavity to form a hollow item. Blow moulding is distinguished by the fact that the technique is used to create hollow objects. This cost effective method can be used to produce a wide array of plastic goods and products.

The procedure involves heating a plastic tube to its melting point (known as a preform or parison) and then inserting it into a mould cavity. They then use compressed air to inflate the molten plastic like a balloon so that it adopts the mould form but is hollow inside. Air pressure and the amount of plastic used determine the thickness of the finished product.

Melting, homogenising, extruding, moulding (blowing), cooling, and ejection are the basic steps involved in the blow moulding process. Different manufacturing facilities may employ additional chilling or heating cycles and the compounding of chemicals and colourants. These other steps depend on the final product’s design and intended use.

Here, we shall be going over and expounding on the different steps that occur during blow moulding:

1.Plastic Resin Charging or Feeding

Plastic charging is the initial step in the process of blow moulding. This is accomplished by transporting plastic pellets to the extruder’s hopper. Vacuum pumps move pellets from large bags or bulk containers to silos or hoppers for raw materials. At the bottom of the silo, a rotary feeder controls the pace of feeding into the plastifier or extruder. The pellets are then transported to the extruder’s hopper using compressed air. Other machines will transfer plastic pellets directly from large bags or bins to the extruder hopper without requiring a separate conveying air system.

2.Melting or Plasticizing

Continuous kneading and heating are utilised to melt the plastic resin as it passes through the extrusion machine. Electric heating elements or heating bands are wrapped around the barrel of the extruder to provide heat for polymer melting. Different portions of the extruder screw serve unique purposes. This consists of feeding, compressing, and measuring. The extruder screw is designed to produce adequate shearing and compression in order to homogenise and extrude the plastic.

3.Preform Injection

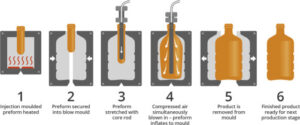

The preform that will later be inflated is being prepared for use in this step. In order for it to form its shape properly, the plastic is injected into a preform mould before being subjected to the blowing process.

4.Clamping or Sealing

A split die that grabs the preform is used in the clamping and sealing processes. The mould will be sealed with the exception of one hole, which is typically the container opening. This hole is where the compressed air will be injected.

5.Blow Moulding and Inflation

During this stage, the shape of the plastic is established. The interior of the preform is then filled with pressurised air. The preform is subsequently inflated to the point where it may be shaped according to the die profile. This is where the preform will be moulded to take its final shape.

6.Ejecting and Cooling

The process of cooling down comes after giving the preform its final form. In most cases, as soon as the plastic comes into contact with the die, it begins to cool at a rate that has been previously determined, thus maintaining the product’s dimensions. After the product has cooled, the mould will open, and it will eject the product, which will be ready for use.

7.Testing for any possible leaks

This is the standard quality control method employed in producing bottles and packaging materials. Either vacuum or compression is created within the container during this process. The system will then measure the pressure to determine if air enters or leaves the container. If a leak is detected, the container is rejected and fed back into the system for reuse.

What are the different kinds of blow moulding?

Here we will be going over the different types of blow moulding that you can utilise to create your plastic products:

1.Extrusion Blow Moulding

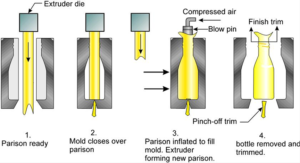

In extrusion blow moulding, a parison of fixed length is extruded while being held in place by a pair of split dies. One end of the parison is sealed, and the other is connected to a source of air. The introduction of compressed air achieves the inflation of the parison. The molten plastic is cooled as it comes into contact with the cold dies, which have been pre-cooled. After the product stabilises, the mould can be opened to release it.

Extrusion blow moulding can be broken down into two distinct varieties, one of which is based on the technique used to extrude the plastic into the parison and the other on the material itself. We can divide blow moulding into two categories, continuous and intermittent:

- Continuous Blow Moulding

In this method, the parison is continuously extruded from the extrusion machine. Polymer homogenising is constantly performed. Once the parison is extruded, it is cut to length by the closing mould halves. These mould halves can be configured into different types according to the mounting and movement of the mould. One configuration is the shuttle press type which can hold single or multiple parisons positioned horizontally next to each other.

The shuttle press is cheaper than the different configurations but has a lower throughput. Continuous blow moulding is suitable for producing small to medium-sized plastic parts requiring lesser investment and less complex operation. However, plastic with proper viscosity and good melt strength must be used to make more oversized products. This is to prevent any sagging that can affect the product’s quality. Continuous blow moulding is also used for blow moulding heat-sensitive plastics such as PVC. This is due to the shorter cycle times that limit the degradation or unwanted curing of the polymer.

- Intermittent Blow Moulding

When there is a sufficient quantity of melt mass in the extruder head or accumulator, extrusion will begin in intermittent blow moulding. At intervals, the contents of the extrusion barrel undergo homogenising and homogenisation. The last of the barrel’s contents are put on hold until a large enough amount has accumulated. The parison can be extruded using a variety of available machines. The most common types of machinery are the reciprocating screw machines and the accumulator head machines.

Large items are typically made using intermittent blow moulding. The essential advantage is the separation of the accumulation and extrusion rates. As a result, huge parisons can be pushed out faster. Shorter suspension times and a modest sagging effect from increased extrusion speed. This means that even with low melt strength plastics, items created from huge parisons are still possible. Using coextrusion technology, extrusion blow moulding can produce a more complex product with several layers.

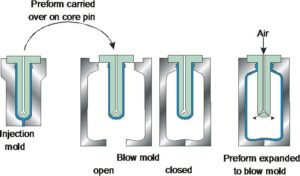

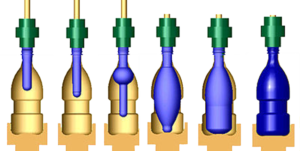

- Injection Blow Moulding

This method combines injection moulding and blows moulding to create the preform. The injection blow moulding procedure begins with the plastic being melted and homogenised. This is commonly accomplished in a plastifier and screw extruder with a reciprocating screw. This functions according to similar principles as the intermittent extrusion method. It is distinguished by using a preform mould with a metal rod in its centre. These metal rods are typically mounted on a rotating table with three parts, each corresponding to a step of the blow moulding cycle. The initial stage is melt injection.

When the batch is finished, it is injected into a preform mould that contains the metal rod. The preform mould comprises two dies, one of which is fixed and the other of which is moveable. After injection, the plastic’s temperature is decreased until it attains sufficient viscosity to retain its shape. The preform is transferred into the second set of moulds with the final product profile in the second phase. The preforms are then shaped by blowing. After reaching the desired dimensions of the mould, the plastic is cooled before ejection. In the last stage, the die is opened to release the finished product, which is ready to be inspected for leaks.

2.Injection Stretch Blow Moulding

There are two primary approaches to this, the single-stage and two-stage processes. In the single-stage process, both the object’s fabrication and its final blow are carried out by the same piece of equipment. When dealing with little quantities or limited production runs, this technique shines. Plastic is initially injection-moulded into a preform for the two-step procedure.

After cooling, the preforms are bundled and fed into a reheat stretch blow moulding process. Injection stretch moulding allows for very high production quantities with few constraints on bottle design but at a high initial investment cost and a big footprint.

What are the advantages of utilising blow moulding?

The blow moulding process has numerous advantages over conventional plastic production methods. Blow moulding is a cost-effective alternative compared to injection moulding, as production and machinery being used are often less expensive than injection moulding. One-piece goods are ideally suited for blow moulding. It can produce items that do not require assembly or joining of halves. Blow moulding has pushed boundaries in the manufacturing industry by enabling companies to use it as their primary production method to meet customer demand when they order bulk plastic products and packaging. This plastic manufacturing method has given companies multiple benefits, including fast-paced production and efficiently creating a high volume of outputs.

Bottom line

The process of blow moulding is one of the most cost-efficient ways to manufacture your goods. It is also a fast and efficient method for producing your products in large quantities. If you need a large number of products you want to stock up on quickly, blow moulding is the viable option you can choose, and we highly recommend it above any other method. Utilising blow moulding will allow you to bring your ideas and products to life while being a cost-effective way to mass-produce simple, functional designs in large quantities!